However, there are a couple of things that don't gel.

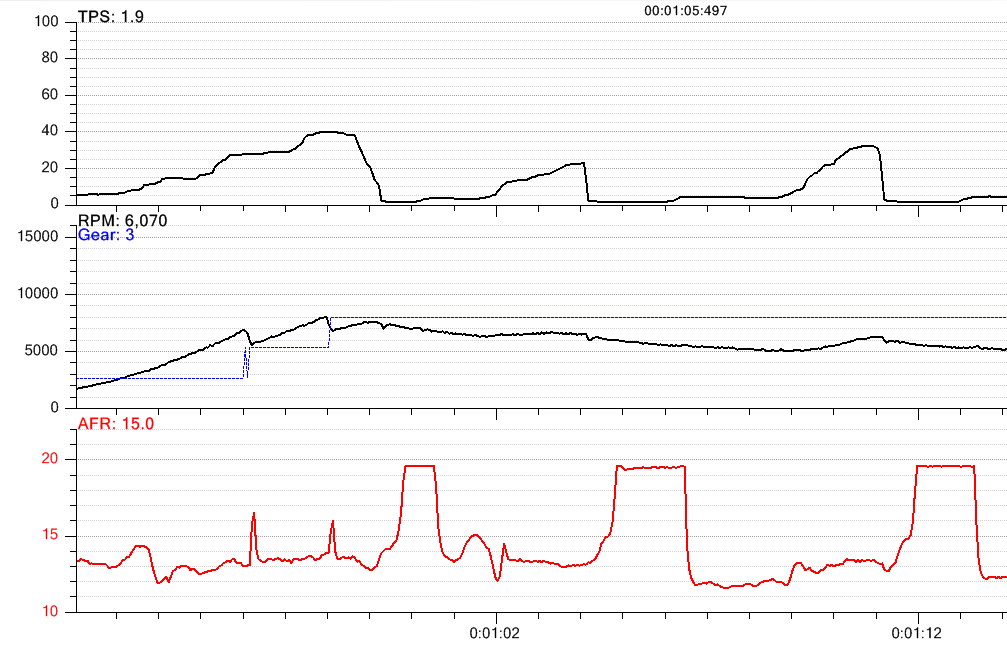

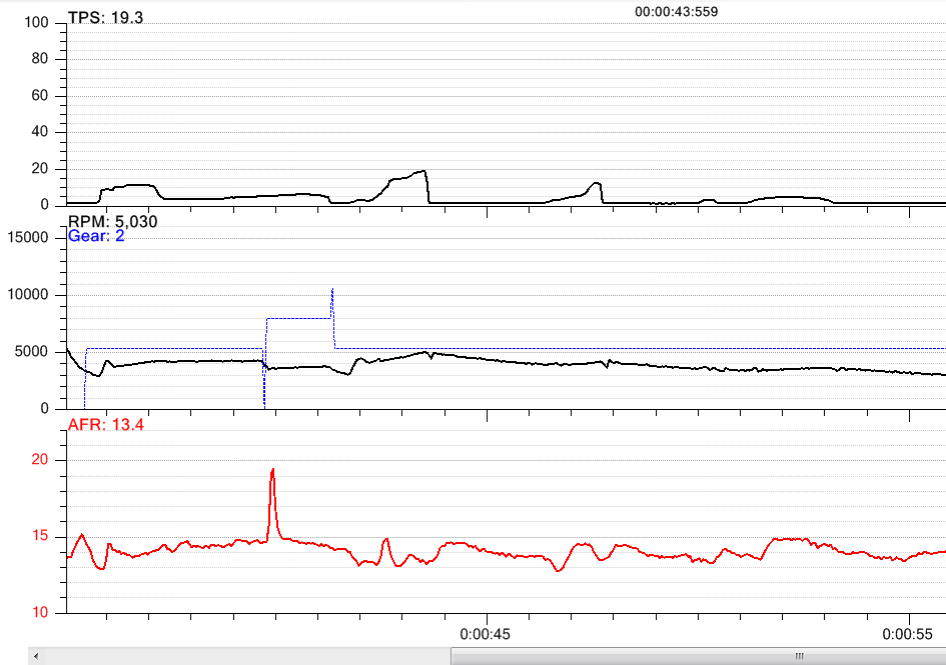

You say the "AFR rises about as fast as the TPS drops". To me there seems to be a delay going lean on TPS closed looking at -JK750-'s graphs. However that's not the issue, it's the opening of the throttle (TPS) and the lag or jerk experienced. From the graphs I'm seeing close to a 300ms delay. O2 sensors are pretty slow and close to 100ms could be attributed to the sensor itself, then there is the response time of the signal conditioning circuitry for the O2 sensor. I guess there would only have to be a 100ms delay in AFR to cause a noticeable jerk. So making sense of the jerkiness from the graphs may be very difficult. What is obvious is it goes to 20~22:1 on overrun and this raises the question of it possibly being the culprit.

There's definitely a delay (couldn't be otherwise unless the ECU could somehow anticipate that the throttle will be closed), but I was talking about rate. Even this though is not really true. The time it takes for the AFR to rise/fall is, on the whole, comparable to the time it takes to open/close the throttle, but the AFR starts rising relatively slowly and then shoots up on close and the reverse on open.

On throttle close this is probably not a problem, as the AFR transition happens once the throttle is closed and the engine is is not making any power anyway. (I recently tried shutting down the engine while engine-braking at low speed and noticed no jerk at all.) On throttle open, the rapid AFR fall happens once you've cracked the throttle open, so it may be able to account for the jerk, but that depends on the effects of AFR on power.

I couldn't find any hard data on how much AFR affects power. I have the vague notion, that AFRs within the usable range, that is, AFRs that don't cause knocking, excessive emissions or other problems, generally don't affect power "too much". I'm thinking along the lines of: say at 4-5000 rpm my engine is making about 40-50HP and also say at 10% throttle I get 10% of that (which is not true generally as the geometry of the butterfly-type throttle doesn't provide a linear plate angle to volumetric efficiency curve; it should be in the ballpark though and perhaps even a bit too optimistic), so I'm making about 4-5HP. If an AFR of 19-20 would make for a 20% change in engine power with respect ot an AFR of 15, that'd be a change of about 1HP. That power change would be delivered in a very short time, but would it be enough to cause a jerk? Perhaps so.

Initially I attributed the excessive jerkyness of my GSXR to a combination of a miscalibrated TPS and an actual fuel cut-off. I theorized that a TPS set too low would cause the ECU to think that the throttle plate is still entirely closed even when it has started to open. When the ECU perceived the throttle as starting to open, it would already be open some way. If before that, fuel had been cut off entirely and is now added again abruptly with a somewhat open throttle, I imagined that could cause the jolt. I'm not sure if that goes a longer way to explain things than the above situation though (and fuel is not cut off entirely anyway so it doesn't matter).

There's another thing to consider here. In my experience, jerks don't necessarily happen when cracking the throttle open, they generally happen when then engine goes from braking the bike to accelerating it. Under high engine speed for instance, it might take quite a bit throttle for this to happen (as much as it takes to coast at that speed). From the curves, we can see that the changes in AFR take place when the engine is still in overrun and the rpms are dropping. It takes quite a bit more throttle for the torque flow to reverse and the rpms to start climbing again. At this point though, the AFR is, more or less, stable.

From experience, I'd expect the jerk to happen at this later time, when the AFR has been smoothed out. Of course, if you open the throttle more suddenly the AFR discontinuities might coincide with engine torque reversal and then AFR enters the picture again. It is quite possible.

In general I think that the major reason for jerks is gear backlash in the drivetrain and chain slack. Whatever the ECU does to aggravate the problem must, I think, happen withing that time-frame when the drivetrain reverses torque and needs to take up the slack and the engine is essentially unloaded. This makes for some pretty tight timing...

The TPS is a known culprit and an incorrectly set TPS at ₋C0 will cause a huge lag or jerkiness. This had been reported by many people. By setting the TPS to ⁻C0 instead of ‑C0 at idle definitely improves the throttle transition but still doesn't cure the lag completely.

Yes, I've also said that in my initial post. In my case though, the initial setting was low, probably because someone adjusted it with the engine off. Once I set it in the middle the throttle smoothed out considerably. I had been trying for months to develop a smooth throttle technique before, with no results whatsoever. Now I almost never get jerks any more. So there is something going on here for sure.

As I said previously, I have designed an electronic circuit that conditions the IAP signal to never drop below idle manifold vacuum. This has cured the lag or jerkiness completely and the throttle transition is liquid or turbine smooth. The exhaust does crackle a lot more now on deceleration and pumps yellow flames out of the exhaust.

[...]

I thought I was having myself on at the huge improvements made, since I designed the circuit myslef. So I took the IAP circuit off. The difference was night and day. Back to its ugly jerky self again. It's on the bike permanently now.

I don't know what else the IAP signal might control within the ECU, but this certainly does seem to support the AFR theory of jerkyness.